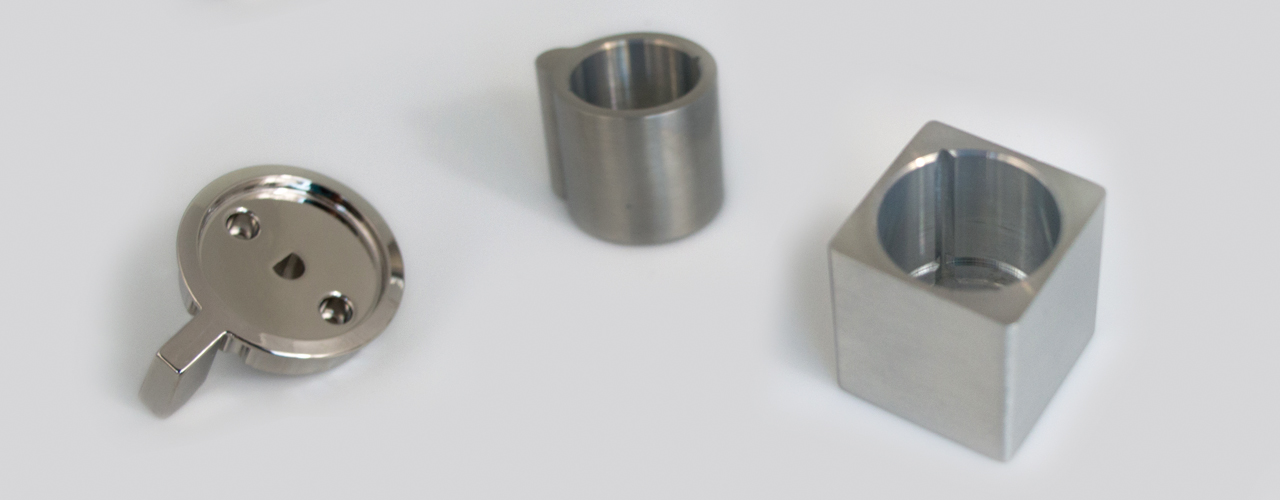

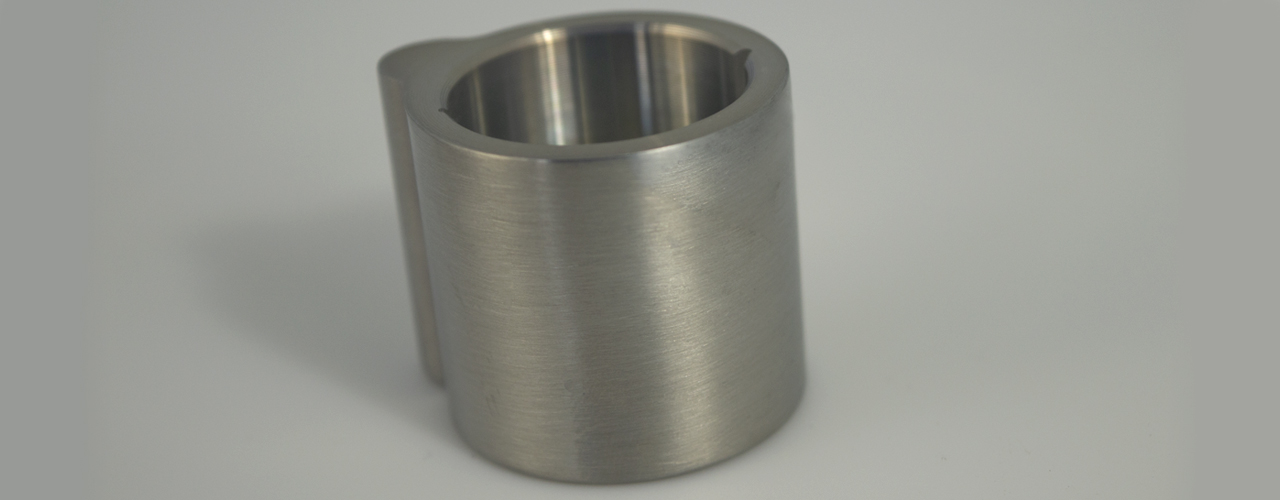

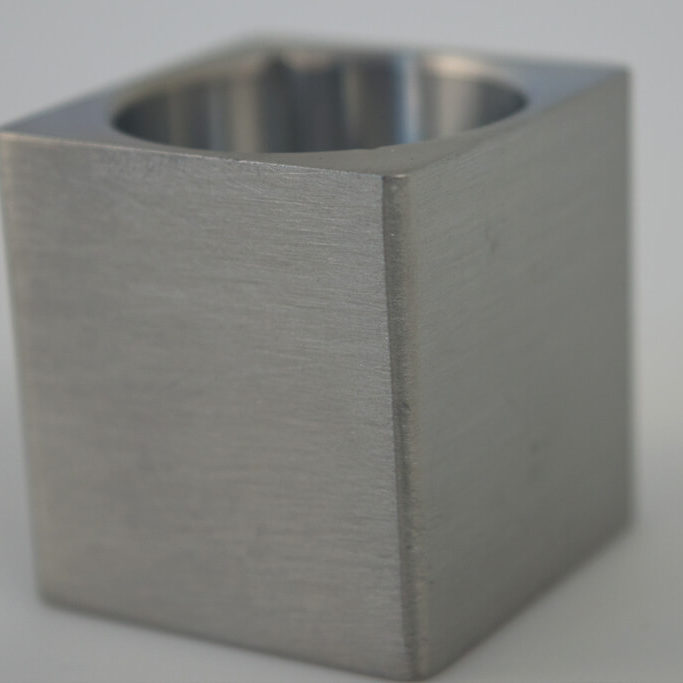

The electroless nickel process aims to make deposits of polished or opaque nickel on both smooth or previously satined surfaces.

Nickel-plating has a main decorative purpose, with thicknesses obtainable and variable from 1 to 50 microns certified, according to the requests.

The objects to be coated with nickel-plating are treated in a solution of nickel salts while the nickel-metal coating is obtained by another electrochemical process.

Good corrosion resistance and excellent esthetic properties are, in fact, particularly suitable for decorative functions.

The corrosion resistance of a nickel deposit depends both on the thickness deposited and on the adhesion of the deposit itself, but – above all – on intermediate treatments such as copper.

The electroplated nickel layer through the nickel-plating is not uniform in its distribution, in particular there will be areas such as the edges where there will be a very marked deposit, while in the holes and in the undercut the deposit will be much lower.

Generally It should be protected with transparent or opaque paints as needed.

Through nickel plating we can coat the following materials after appropriate preparation treatments:

- Iron

- Aluminum and its alloys after special preparation

- Carbon steels also heat treated

- Stainless steels

- Cast iron after sandblasting

- Copper and its alloys

- Brass

- Zamak

The maximum dimensions of the parts that we can work are 1600x1100x300.

Possibility of de-hydrogenation and / or lubrication with emulsifiable oils.